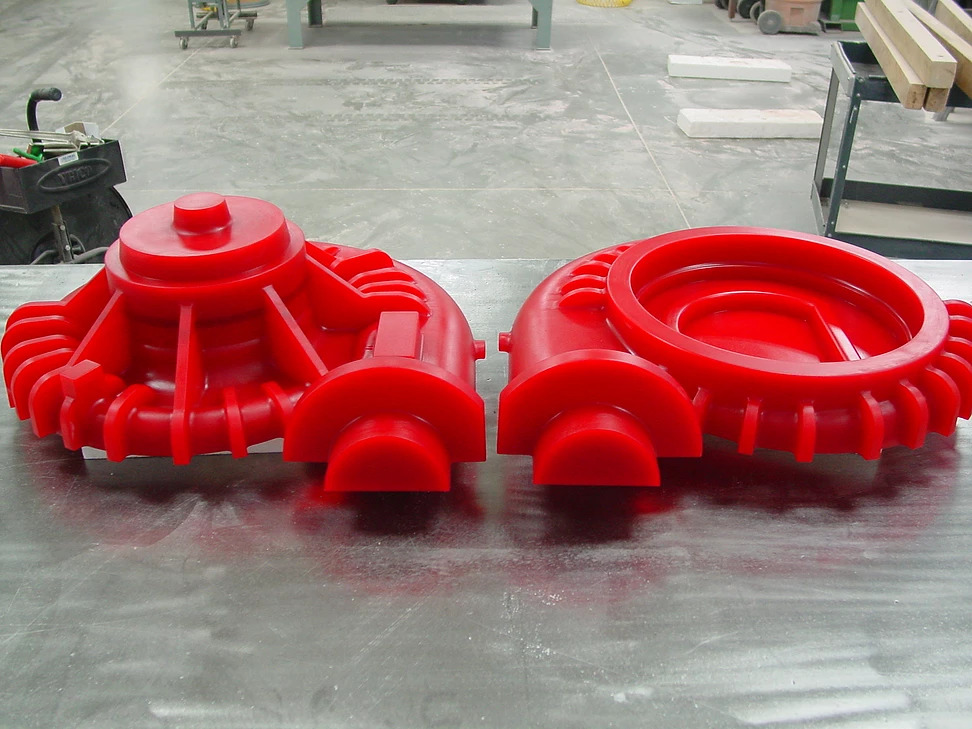

The V-Process was invented in Japan in 1971 as an improvement on conventional sand casting. In this process, a thin preheated sheet of plastic film material is placed over a pattern and a vacuum is applied to draw the sheet to the pattern contours. The flask containing the mold is then filled with dry unbonded silica sand which is compacted by vibration. A second plastic sheet is placed at the back of the flask and the mold is further compacted under vacuum. With the vacuum maintained, the pattern is then removed and the two halves of the mold are joined and secured for pouring. After the metal has solidified, the vacuum is removed and the casting is released. One big advantage to the V-Process is, pattern life is longer because there is no contact between the sand and the pattern.