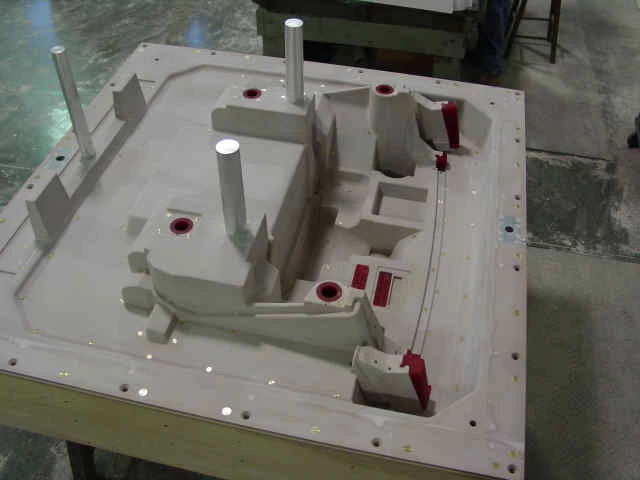

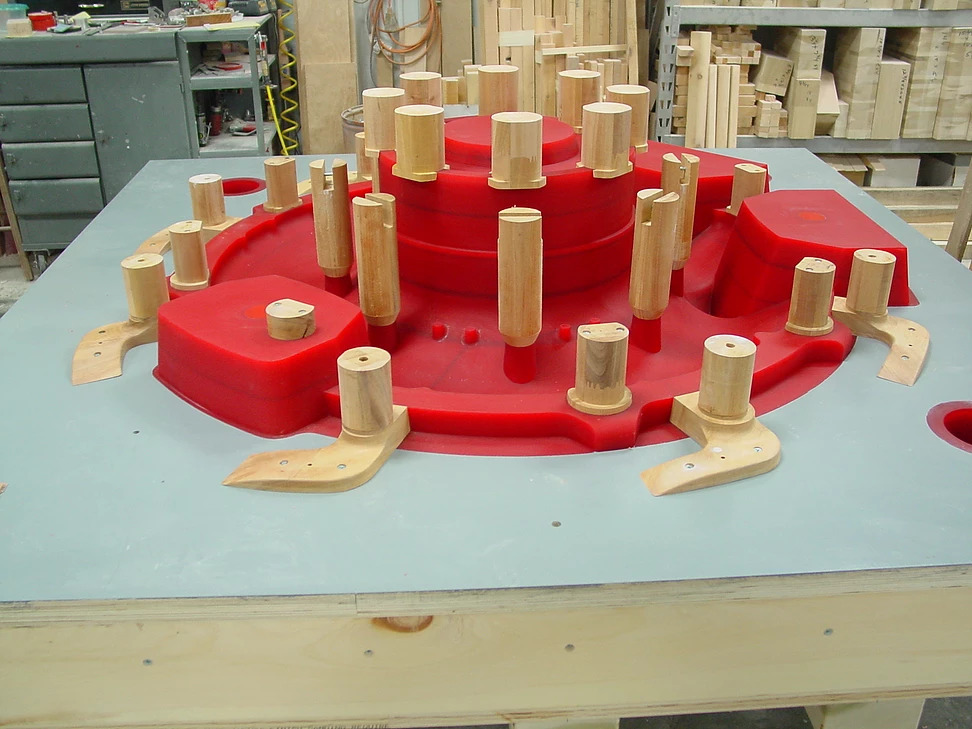

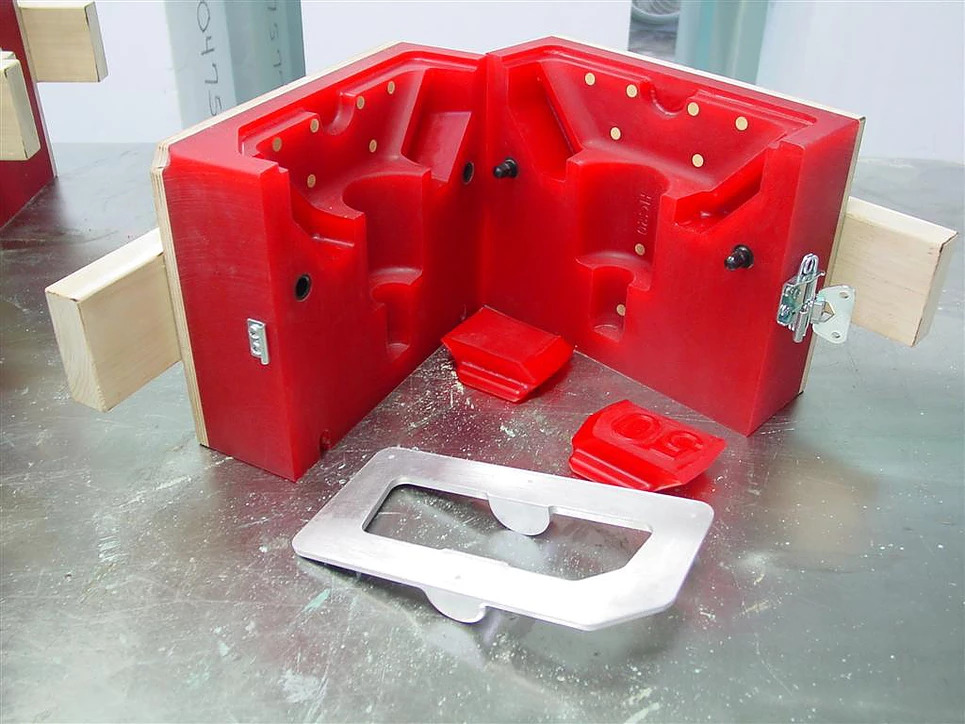

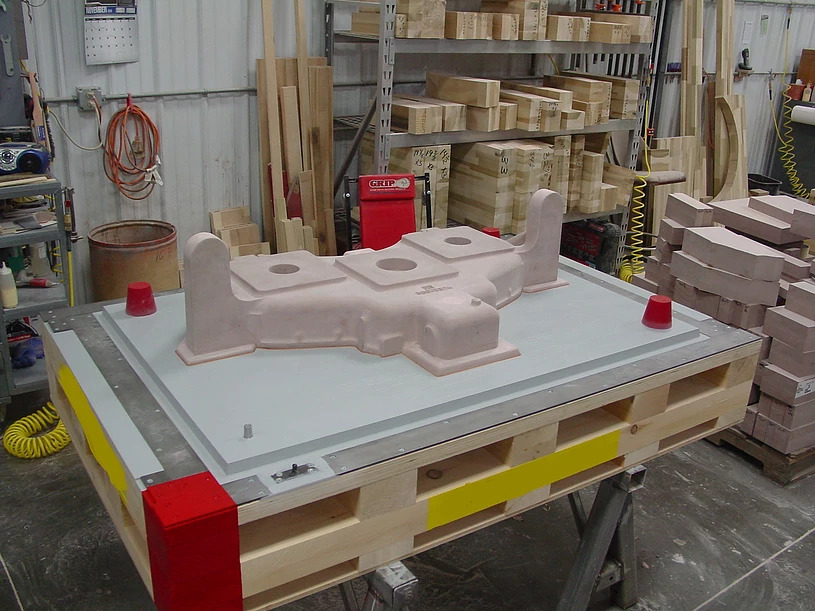

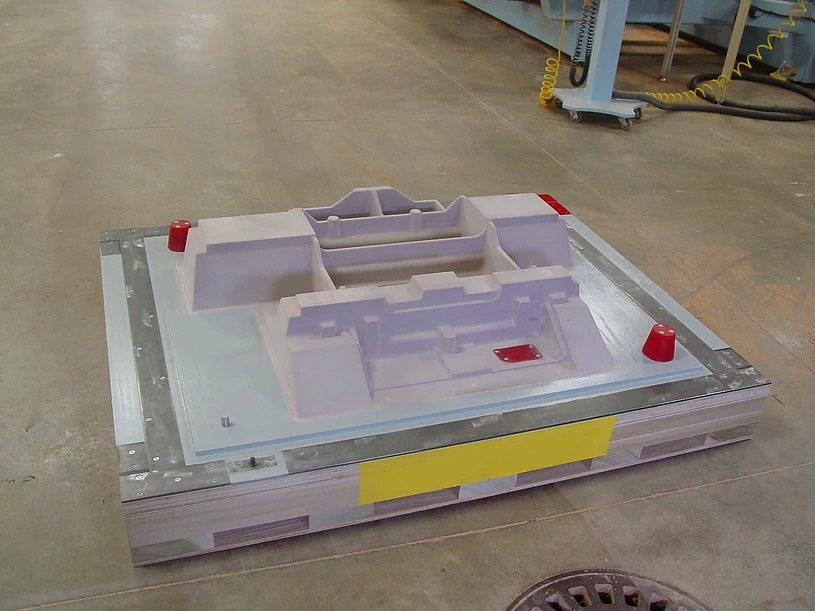

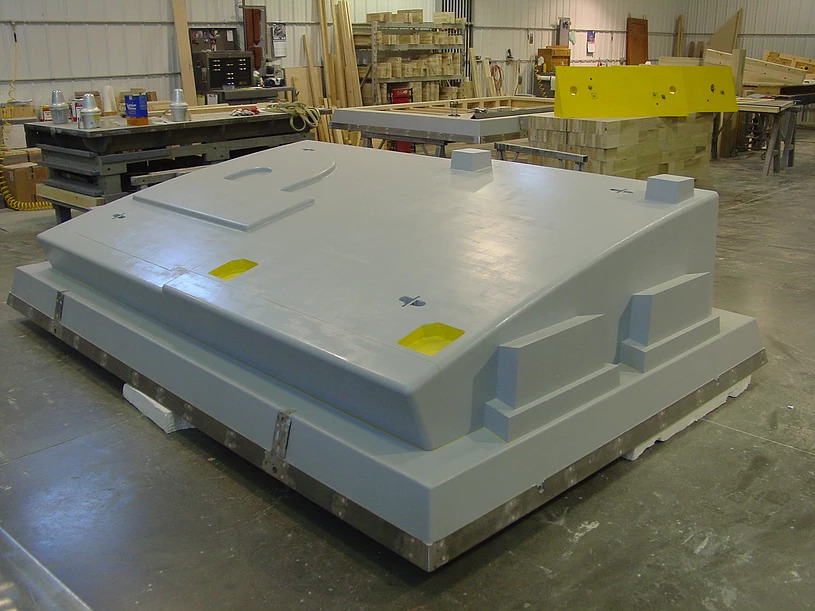

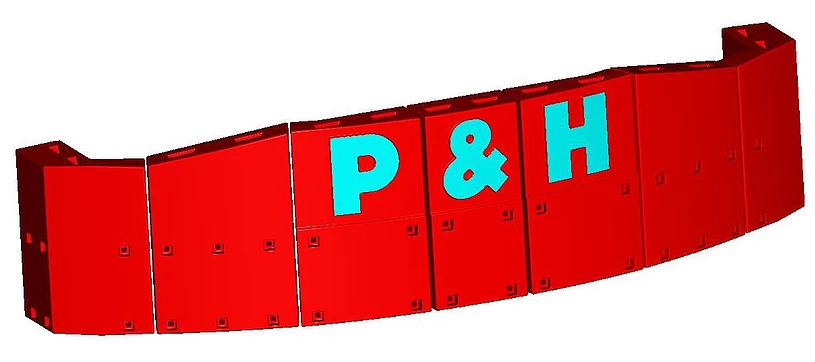

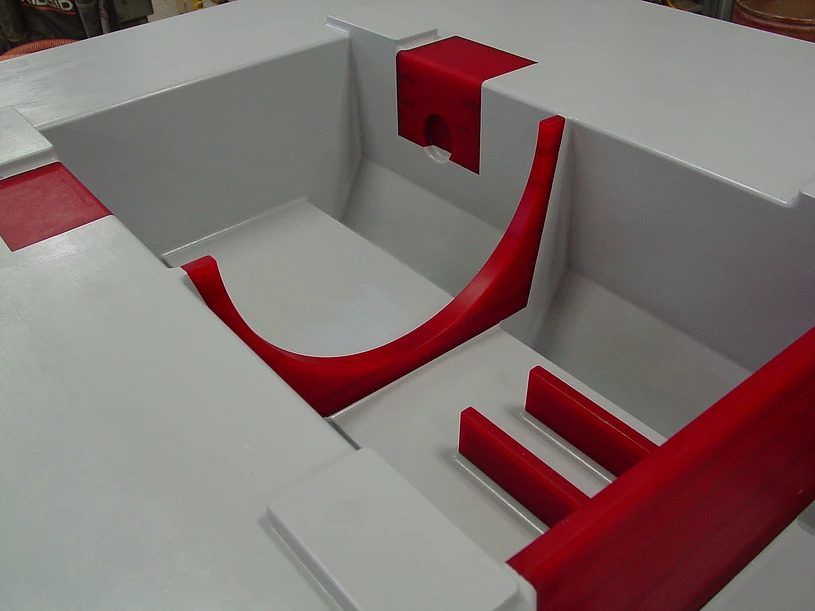

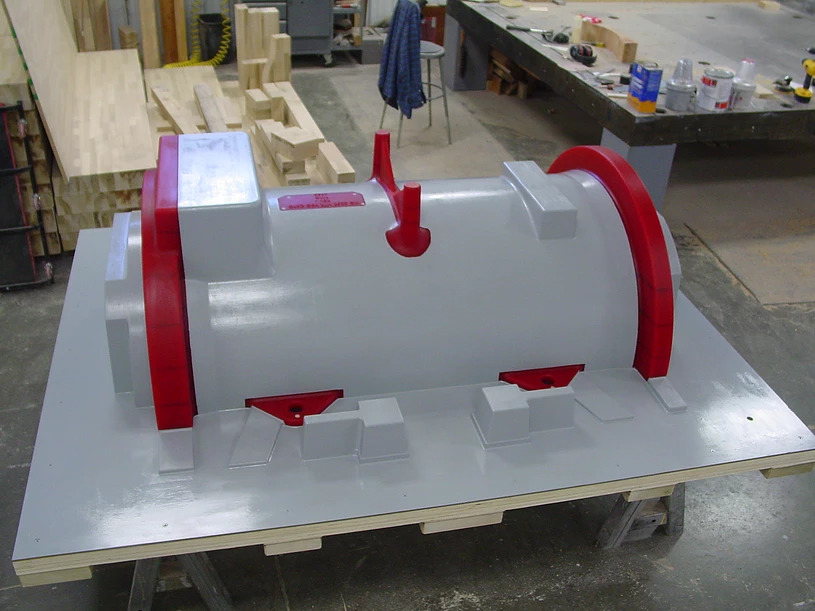

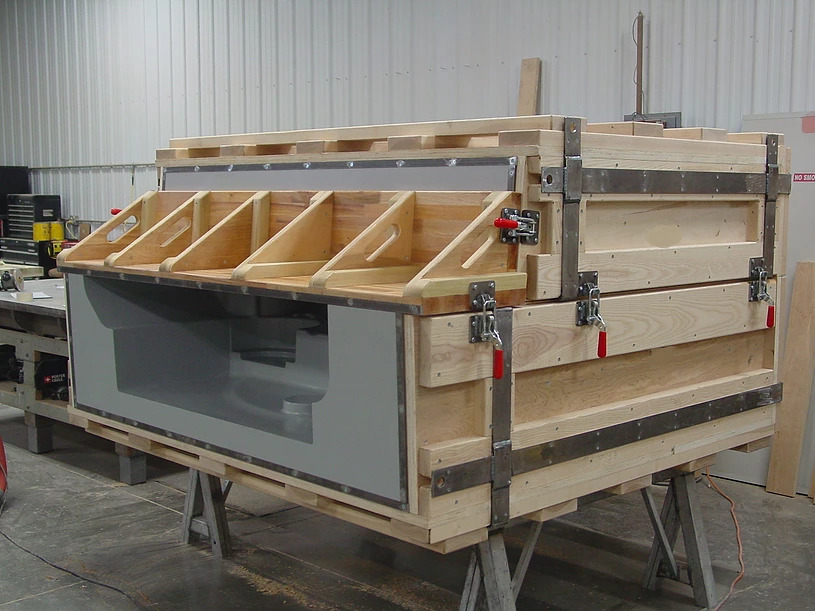

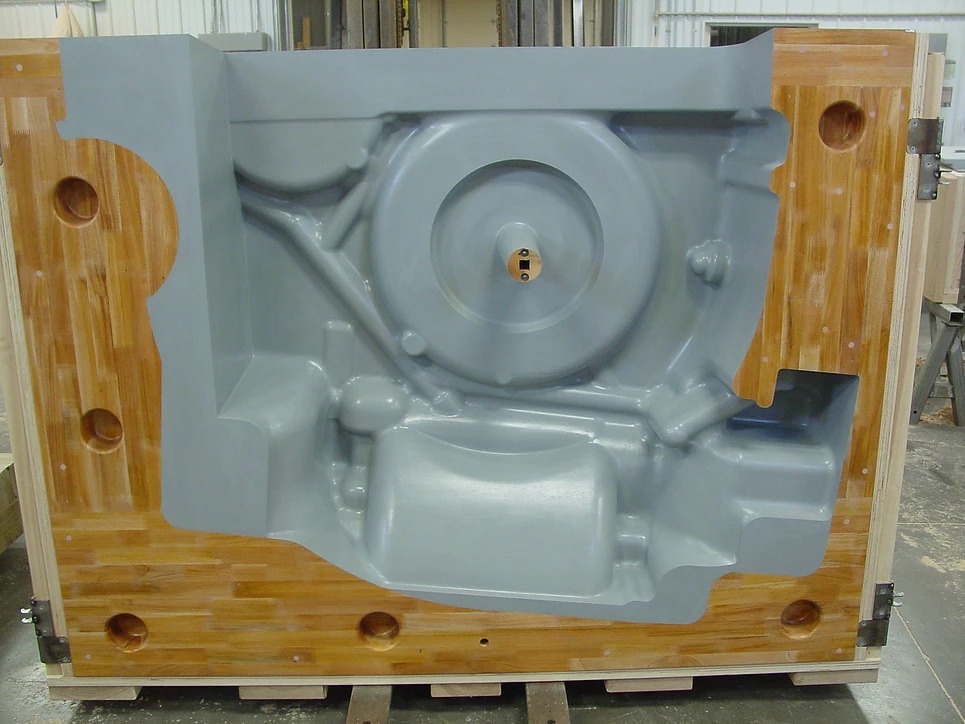

Pattern Services is capable of supplying you with wood masters or molds for making fiberglass components. We can also scribe lines on the molds that will show up on the fiberglass parts and aid in trimming them to final size. For very large molds we can make them in smaller pieces all indexed or pinned together for later assembly at the customers site.

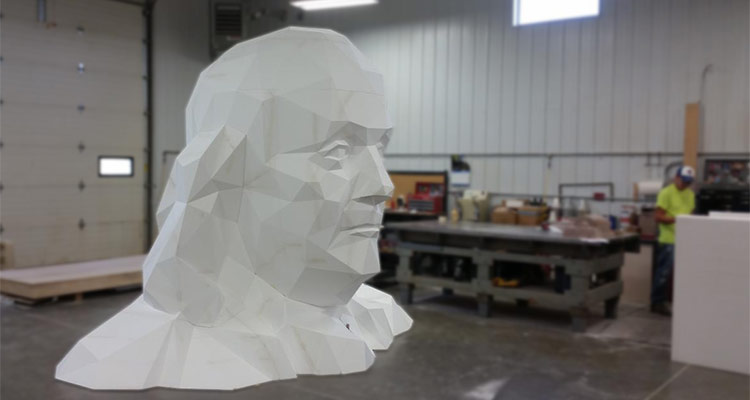

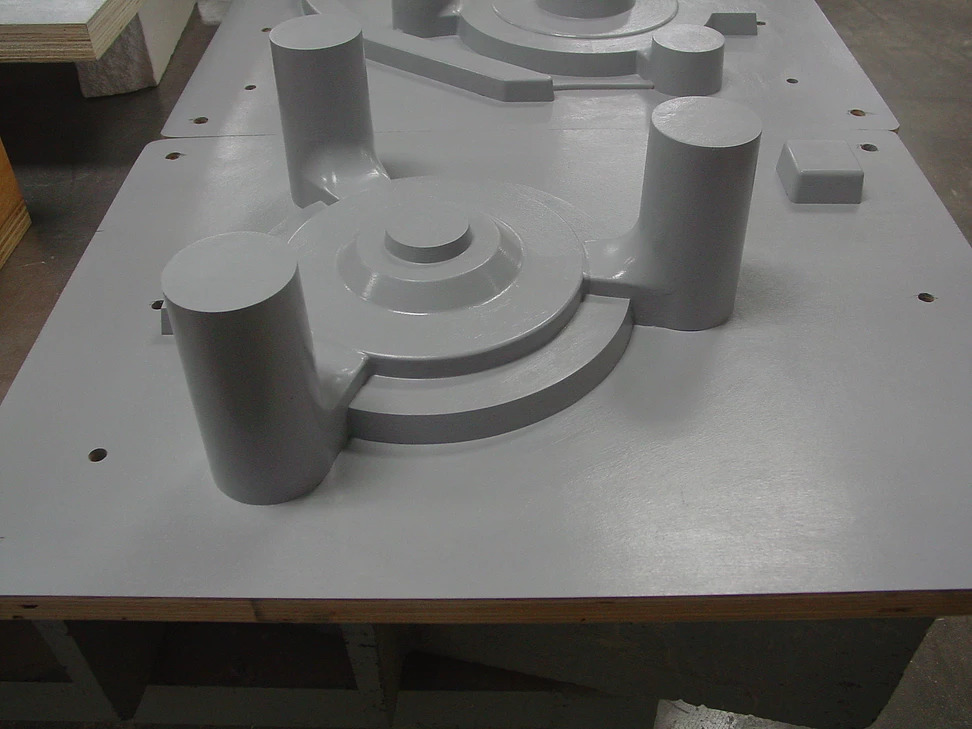

Pattern Services has the ability to cut styrofoam shapes for display or use at trade shows. In most cases the customer will coat the styrofoam with a hard shell and paint it for a realistic look. We also can cut decorative panels for furniture, architectural trim and moldings.

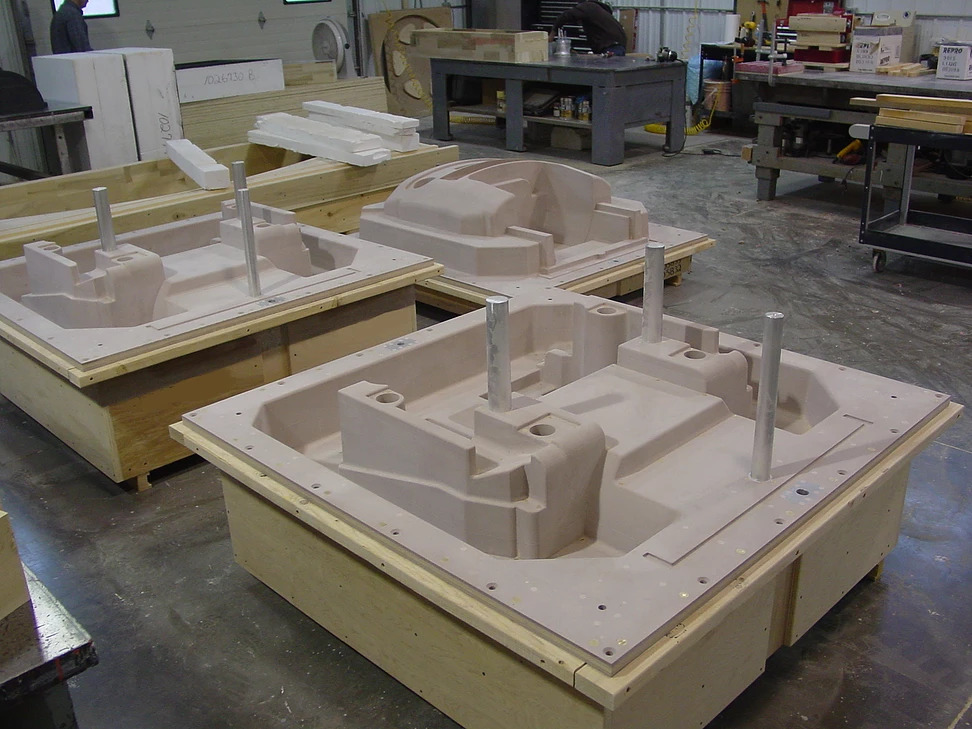

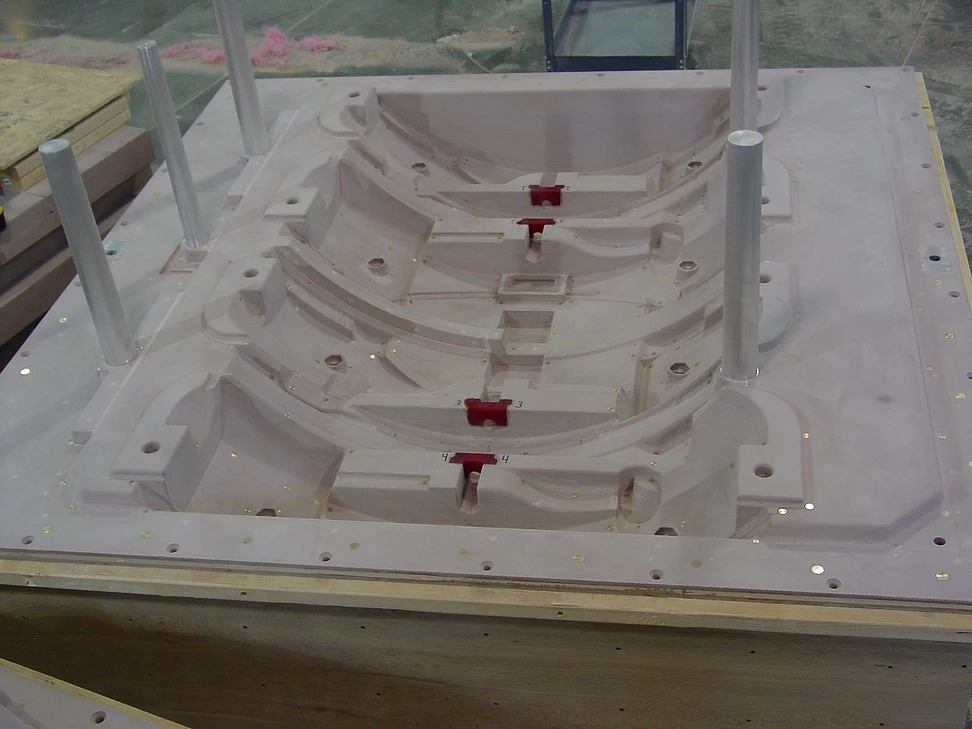

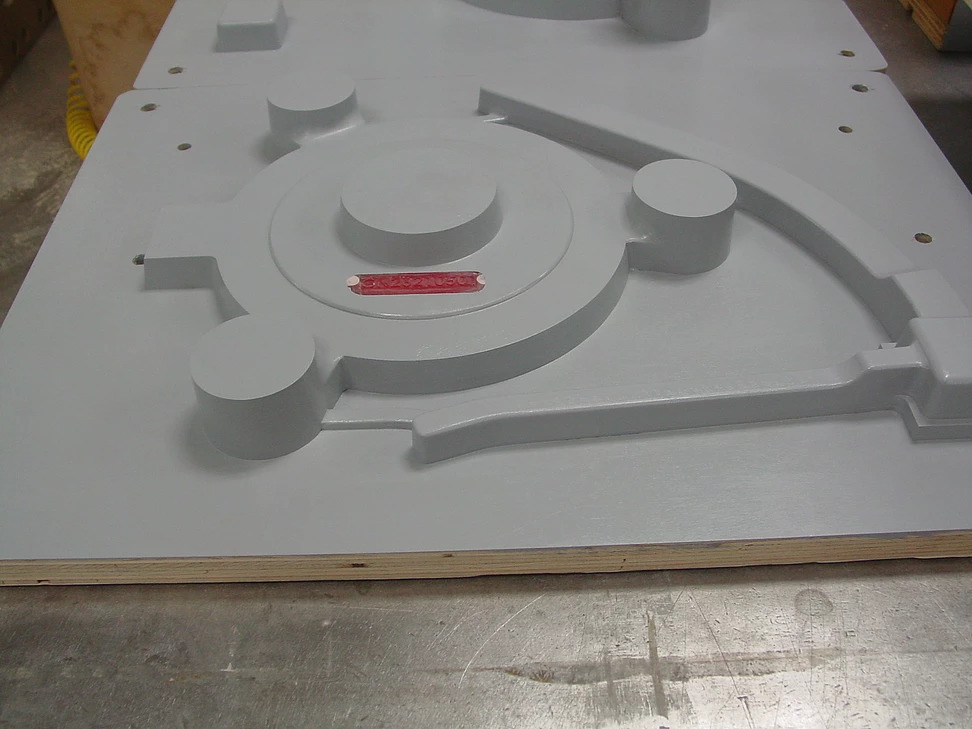

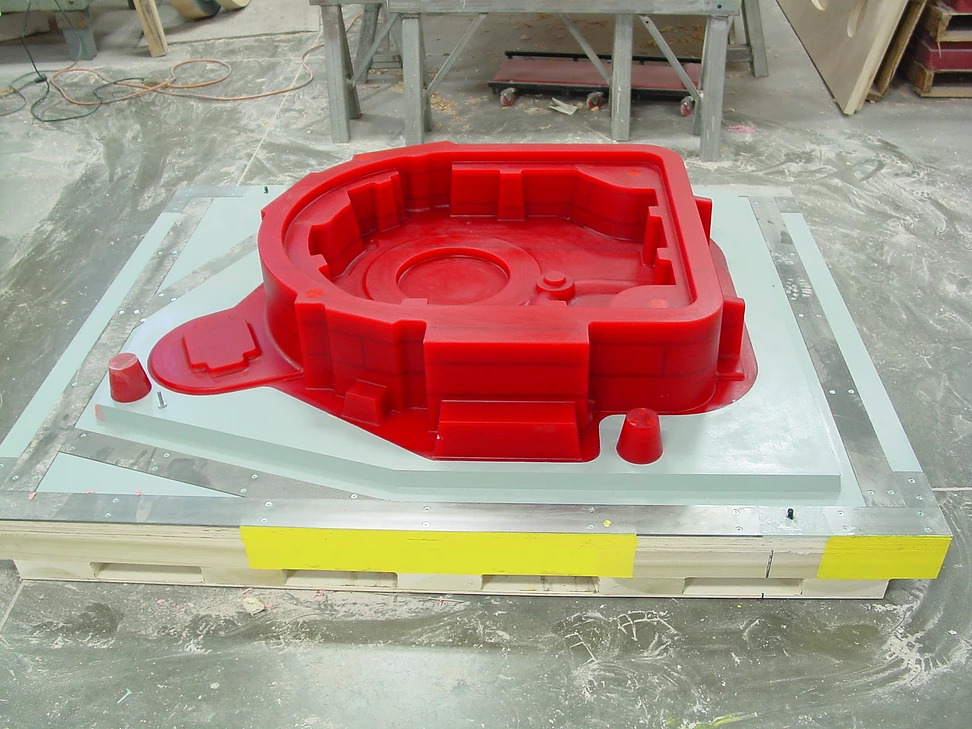

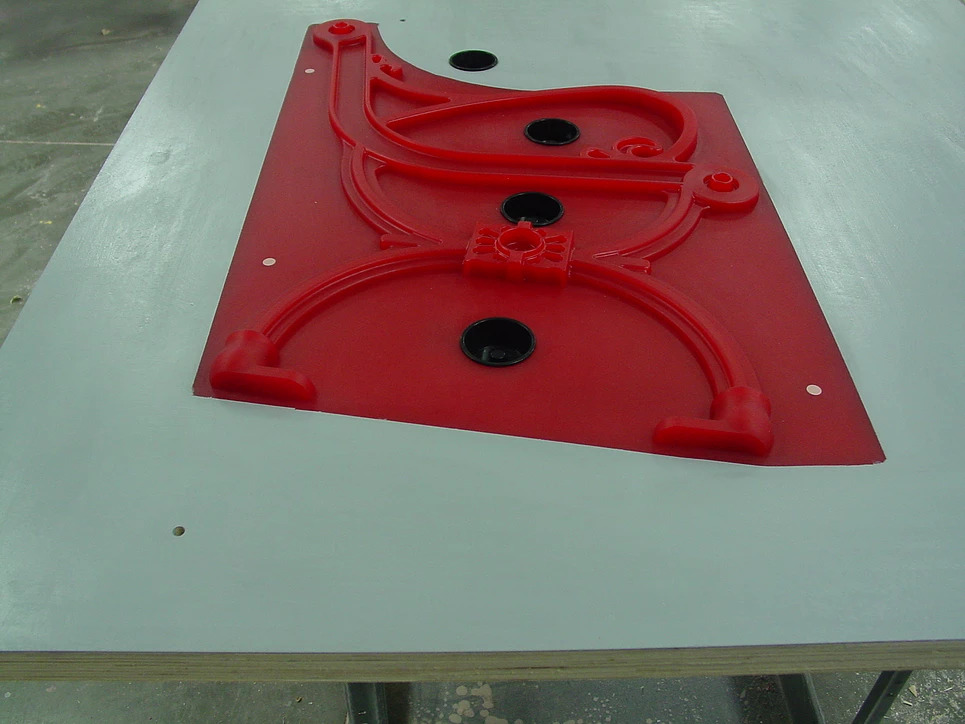

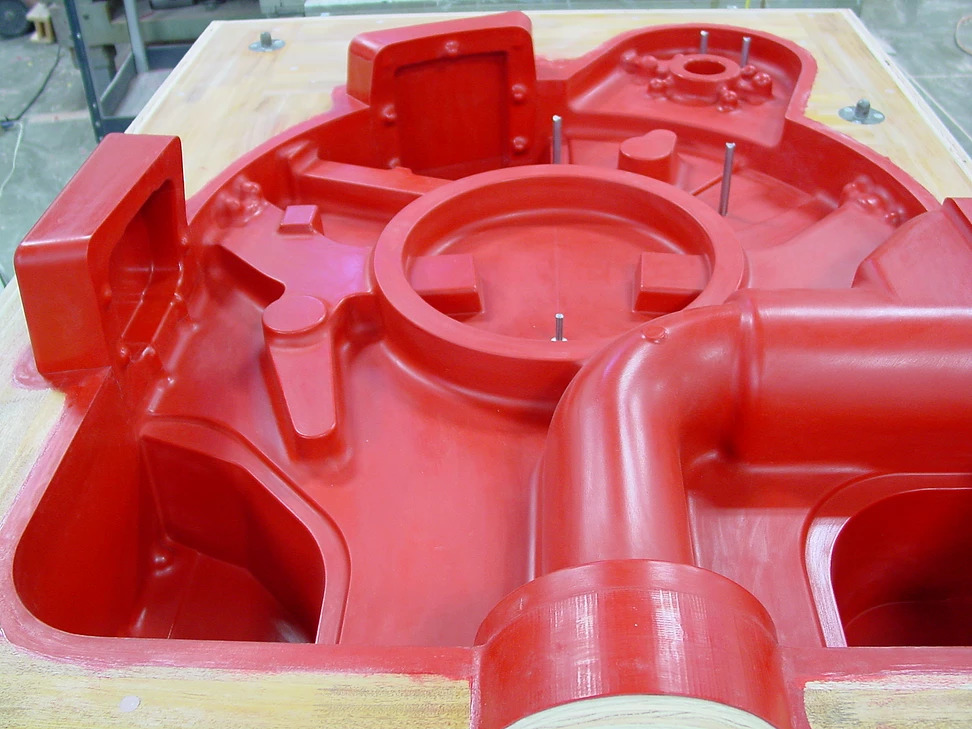

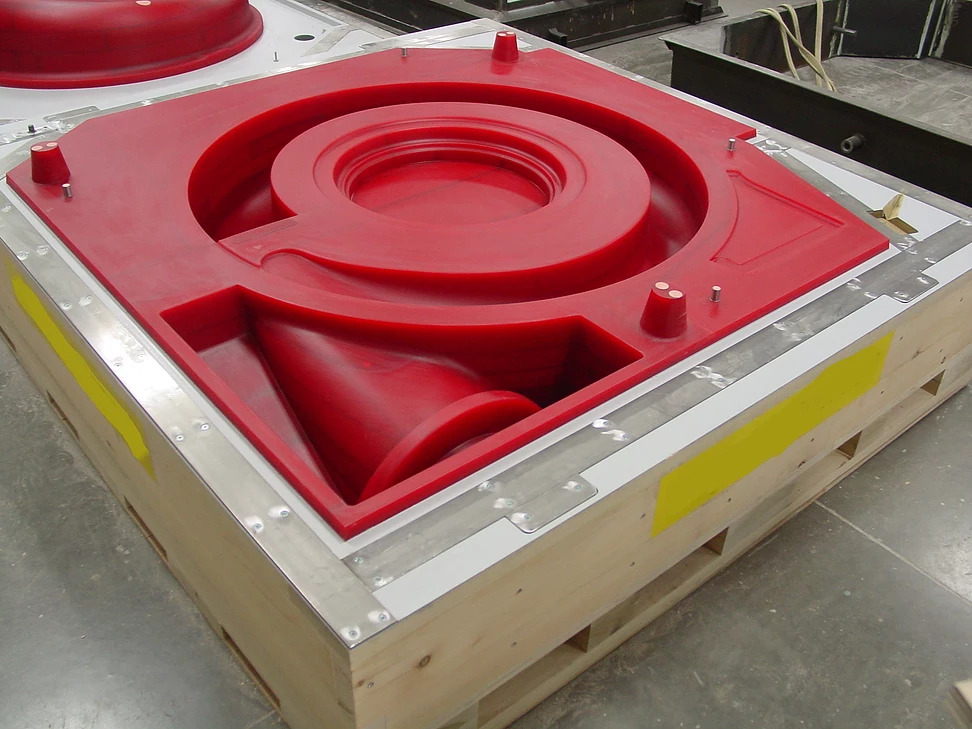

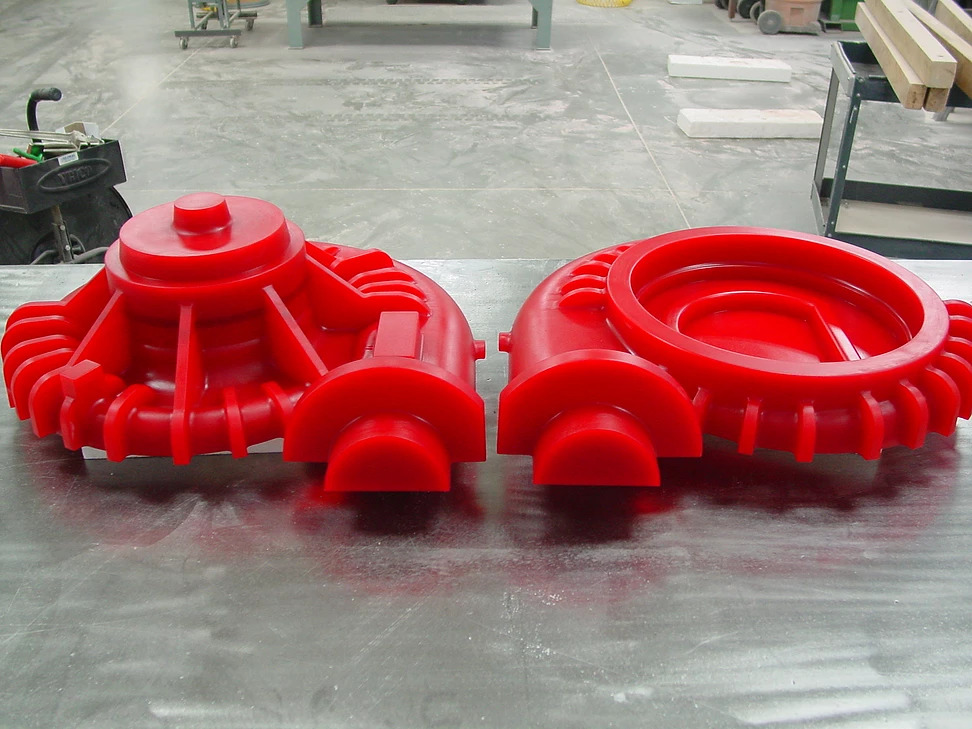

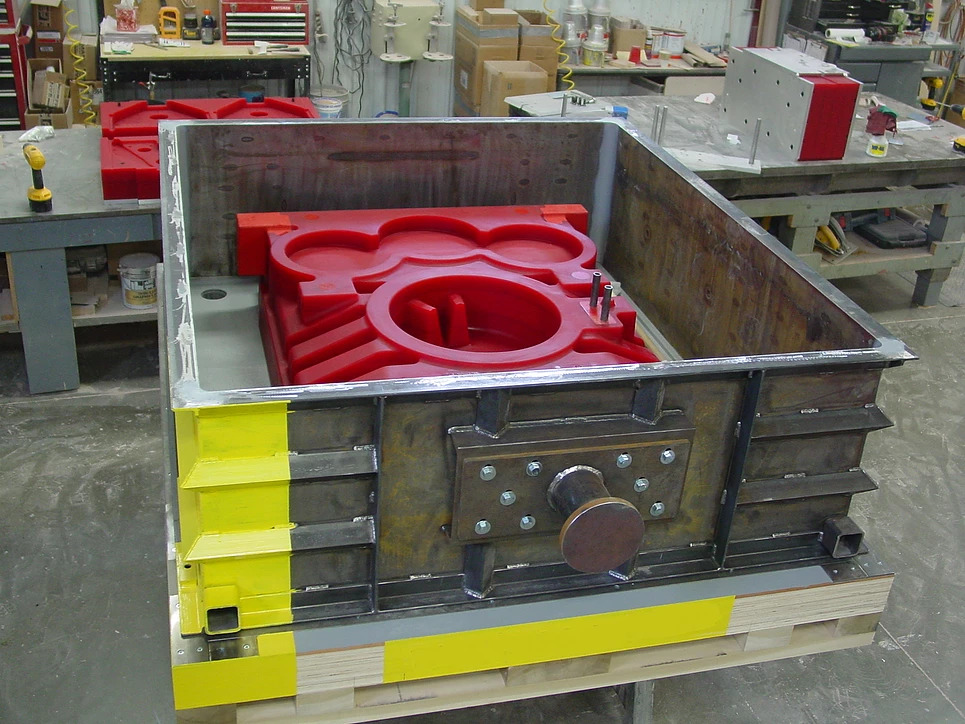

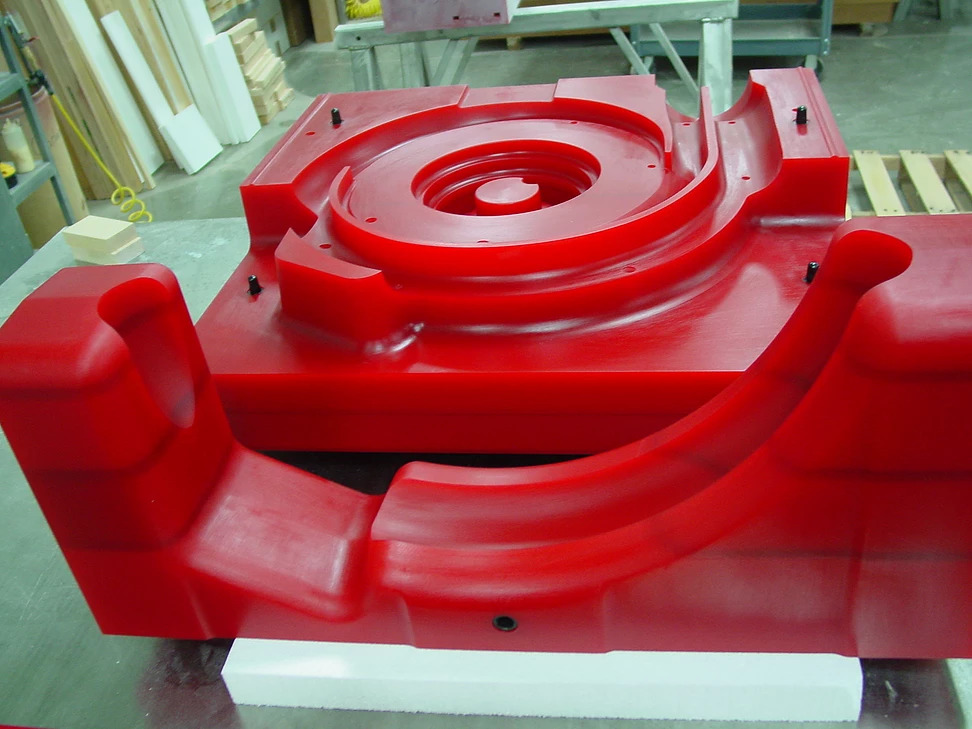

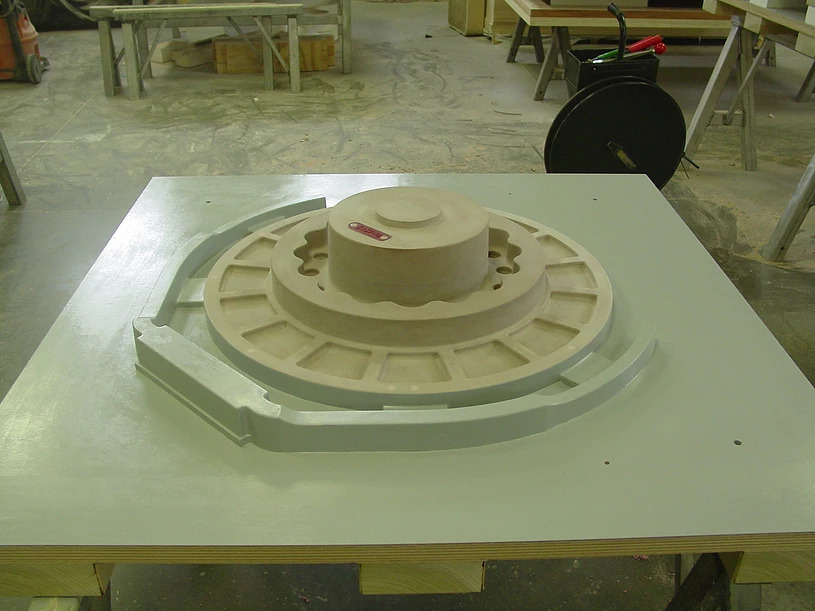

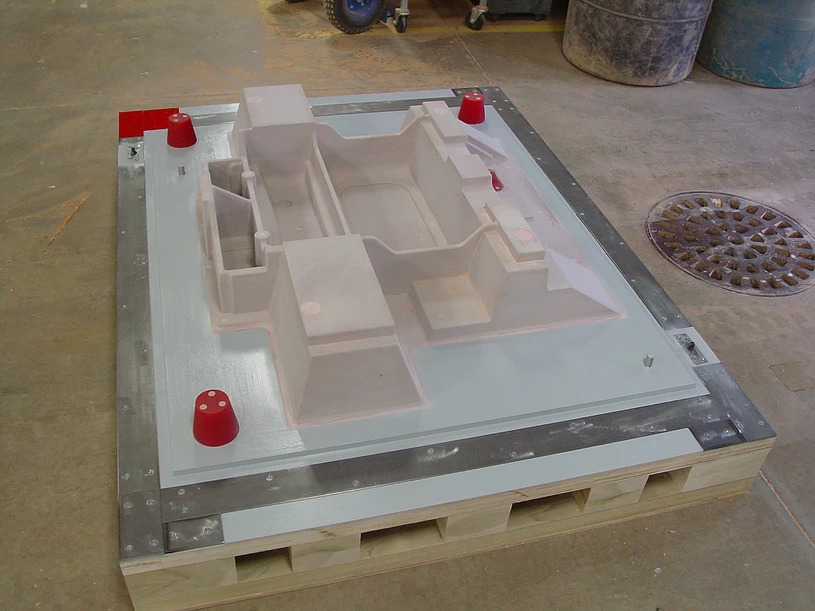

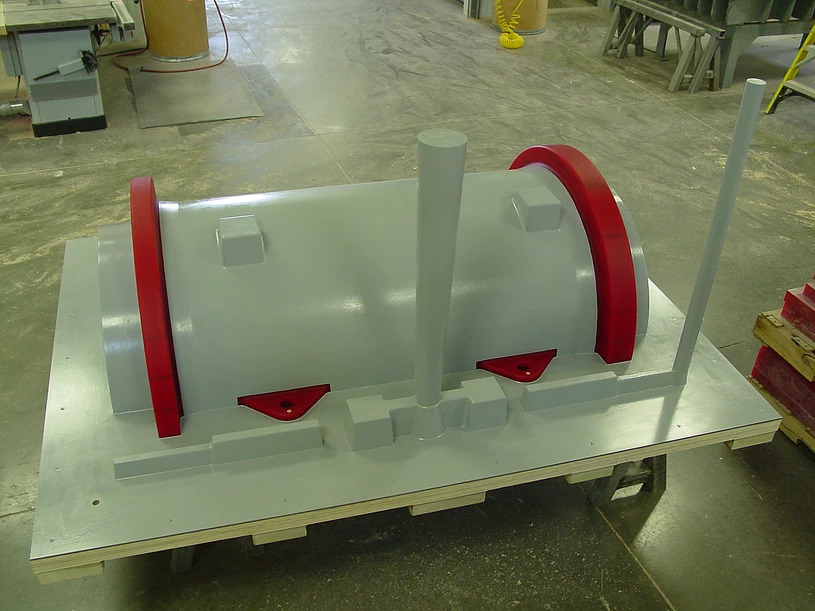

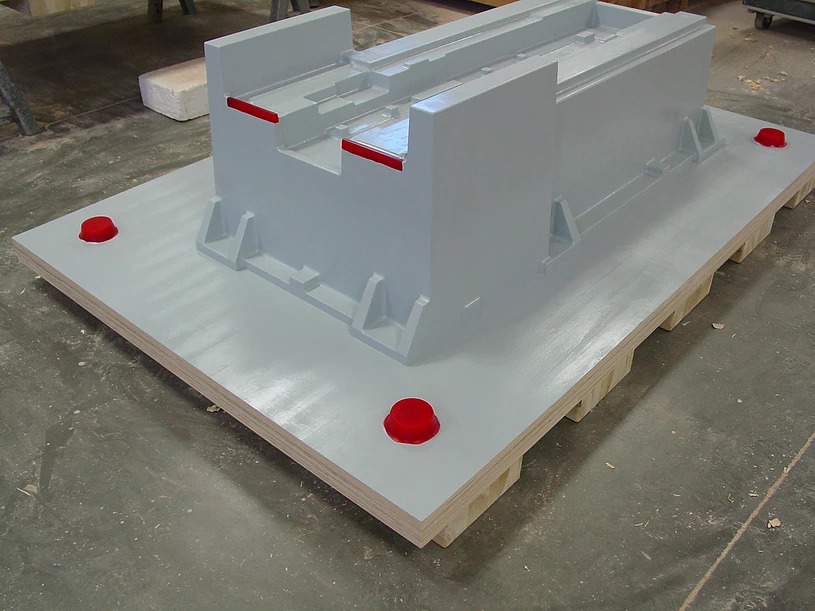

The V-Process was invented in Japan in 1971 as an improvement on conventional sand casting. In this process, a thin preheated sheet of plastic film material is placed over a pattern and a vacuum is applied to draw the sheet to the pattern contours. The flask containing the mold is then filled with dry unbonded silica sand which is compacted by vibration. A second plastic sheet is placed at the back of the flask and the mold is further compacted under vacuum. With the vacuum maintained, the pattern is then removed and the two halves of the mold are joined and secured for pouring. After the metal has solidified, the vacuum is removed and the casting is released. One big advantage to the V-Process is, pattern life is longer because there is no contact between the sand and the pattern.

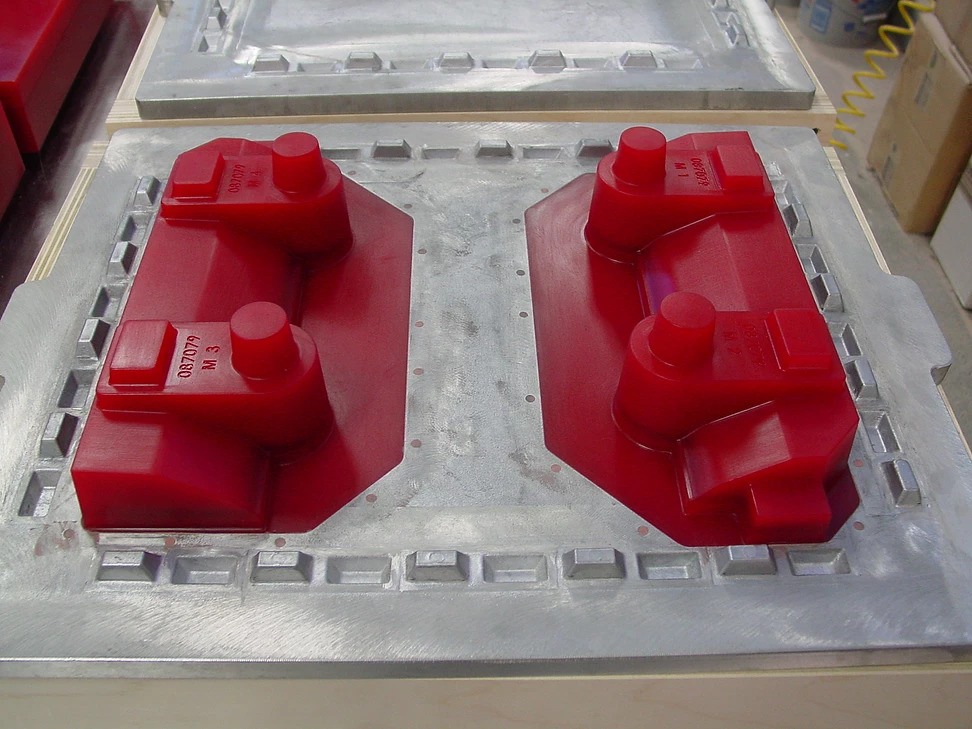

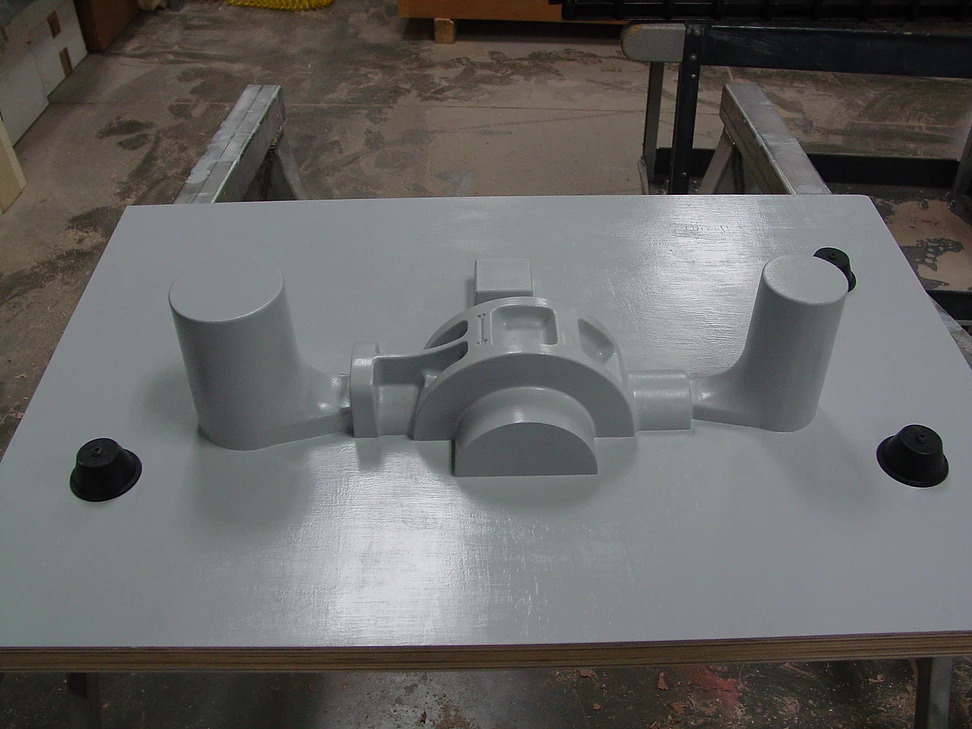

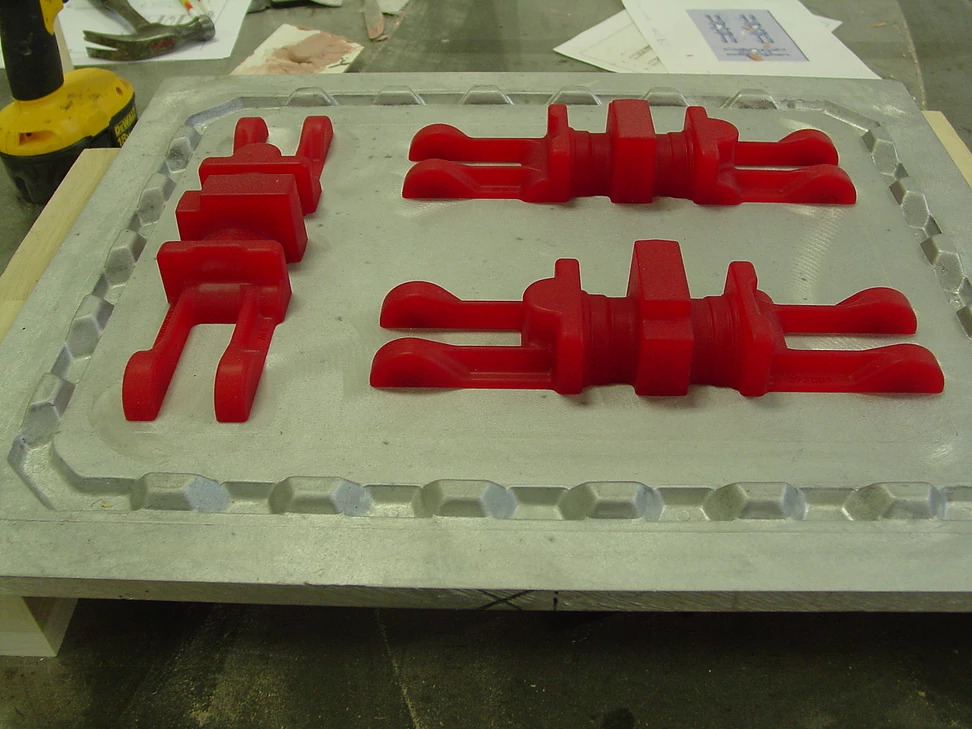

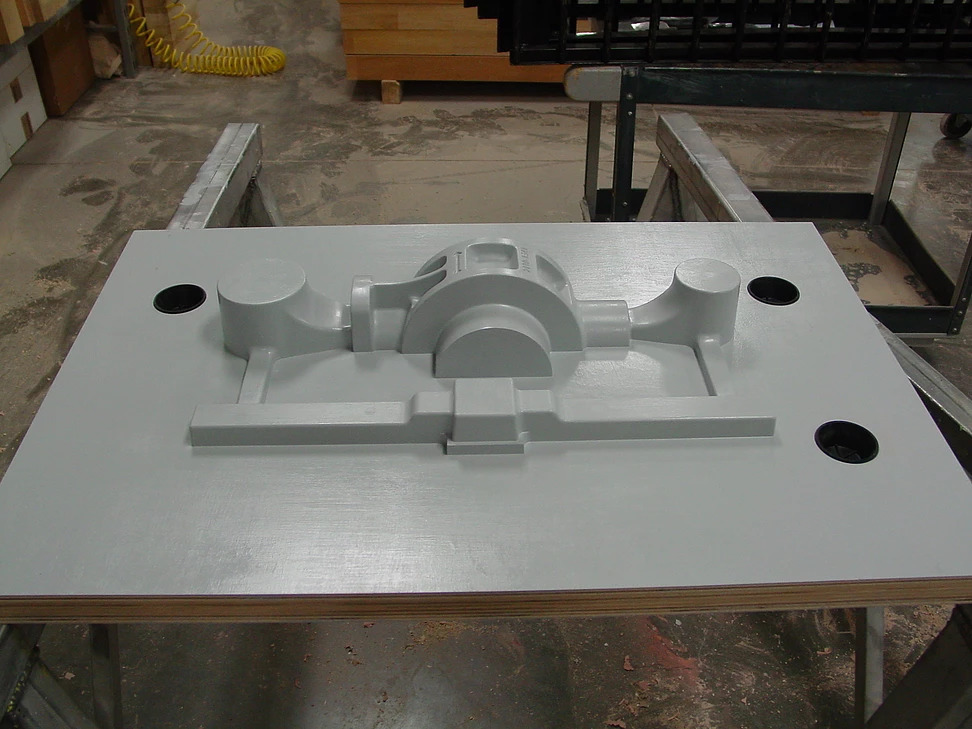

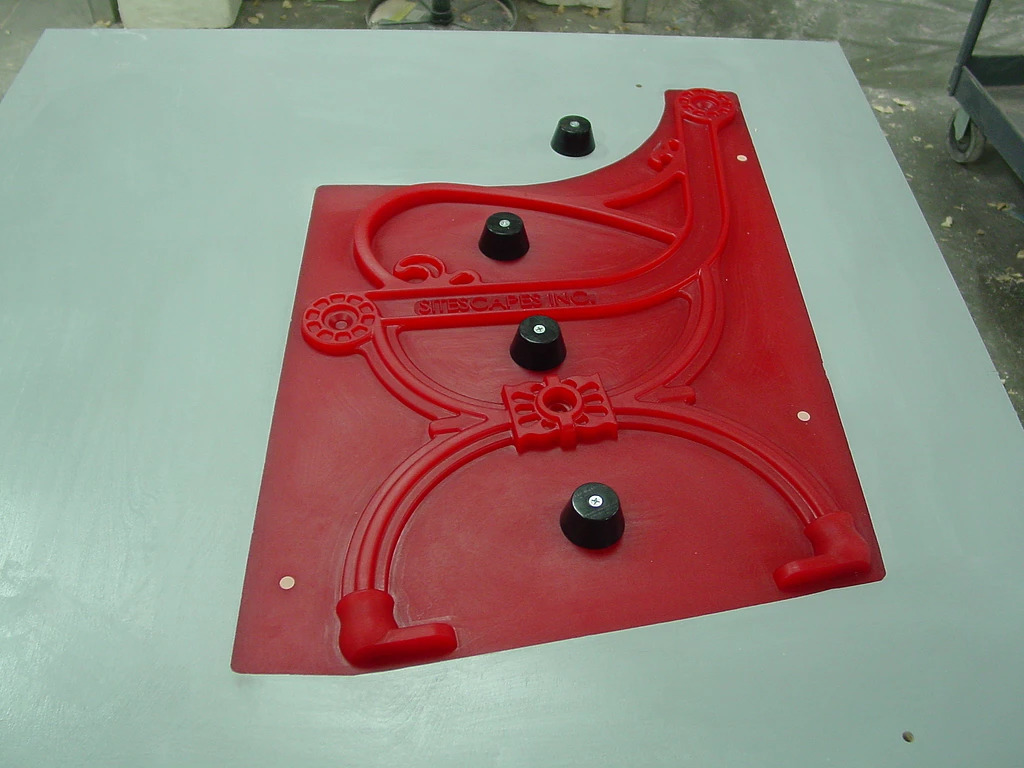

Pattern Services is capable of producing match plate patterns in wood for smaller production needs and aluminum and red board for higher production. If the customer supplies us with gating information we can machine the gating right on the board.

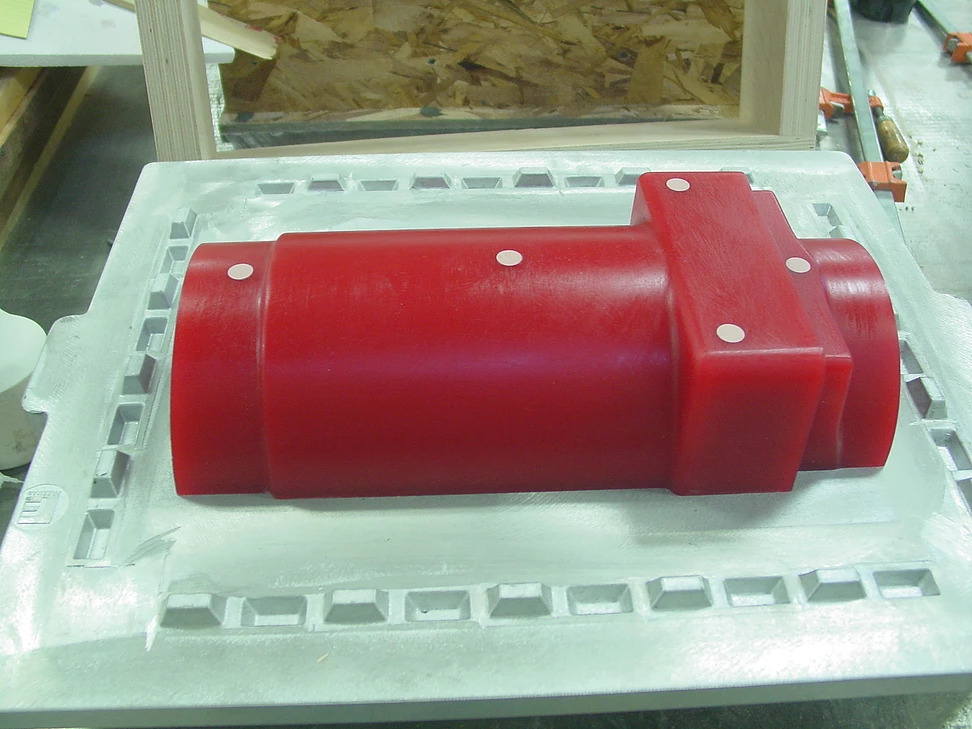

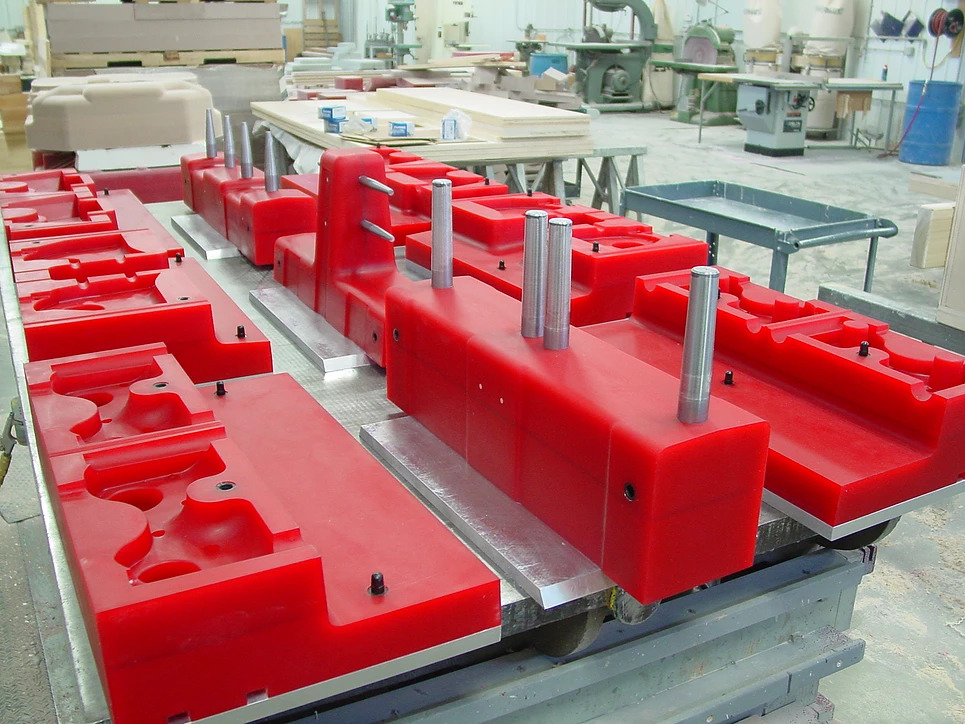

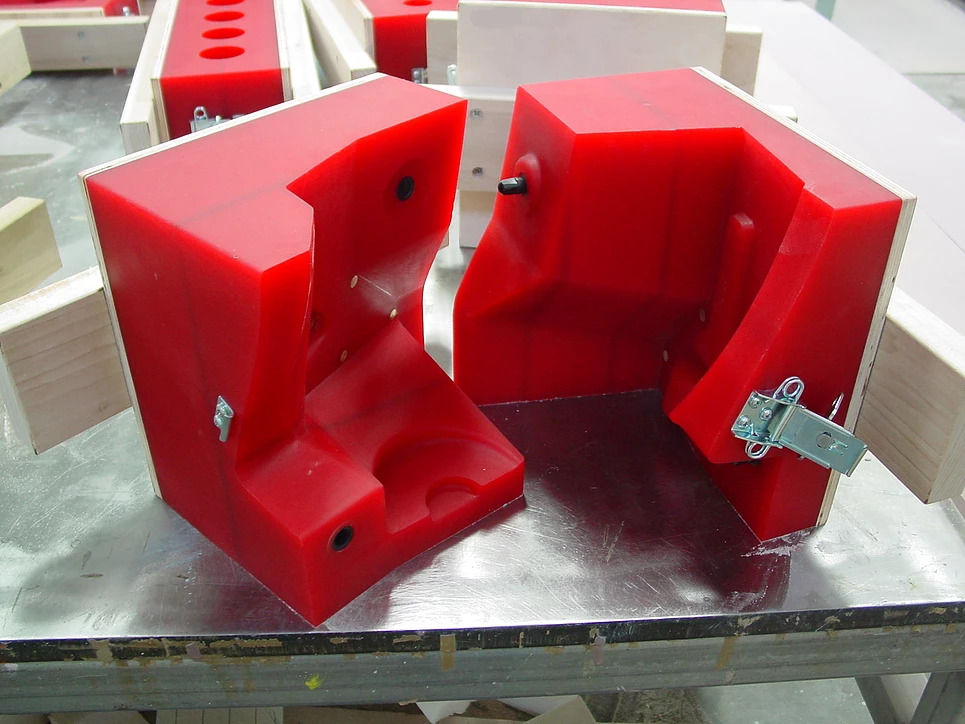

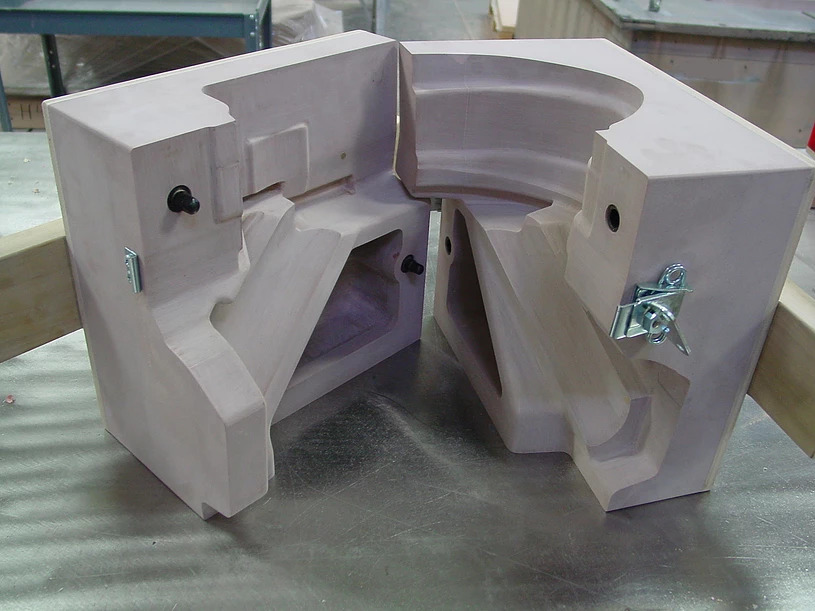

For your higher production needs, Pattern Services can Machine your tooling from Red Board or if you prefer we also are capable of doing poured urethane, both of which have a high abrasion resistance. Steel Stripping of core boxes and boards or steel faced boards, aluminum loose pieces are all options based on your specific needs. We can also provide a set of fabricated steel flasks if this is a need.

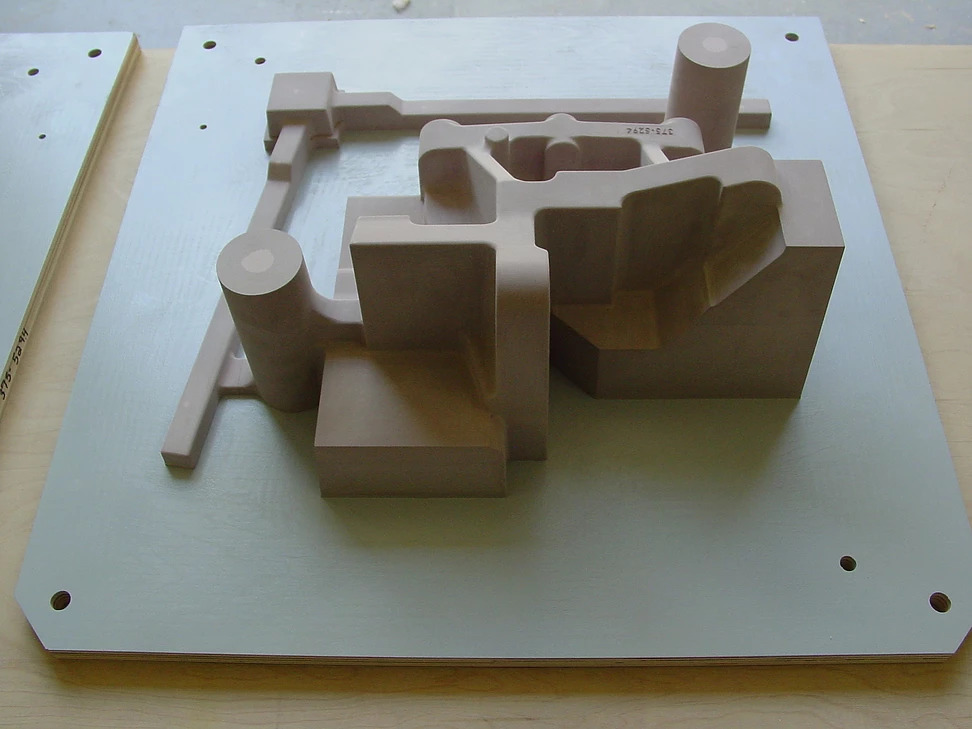

Brown board is a perfect alternative material when there is plenty of complexity to your part, such that it would be difficult to orient wood grain for strength. Brown Board is also more stable than wood and is capable of meeting your low to mid quantity production needs

Depending upon your production needs Pattern Services can construct wood patterns from Pine, Poplar, Mahogany, Maple, and Ash. We pay specific attention to grain orientation wherever possible, and adding stronger materials in thin areas and wear surfaces if necessary.

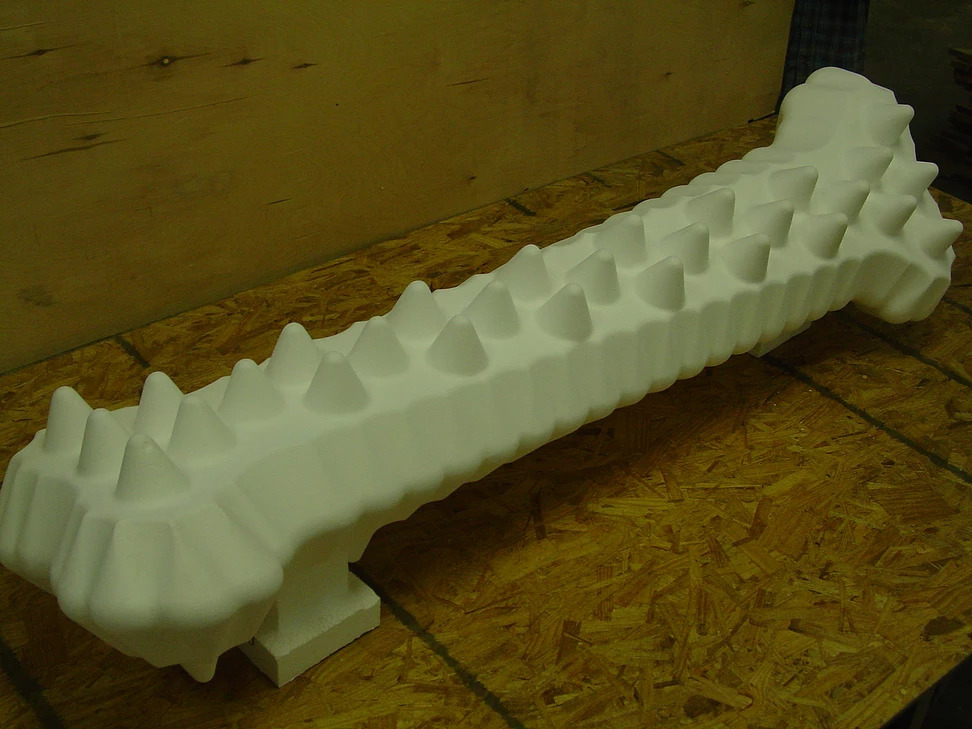

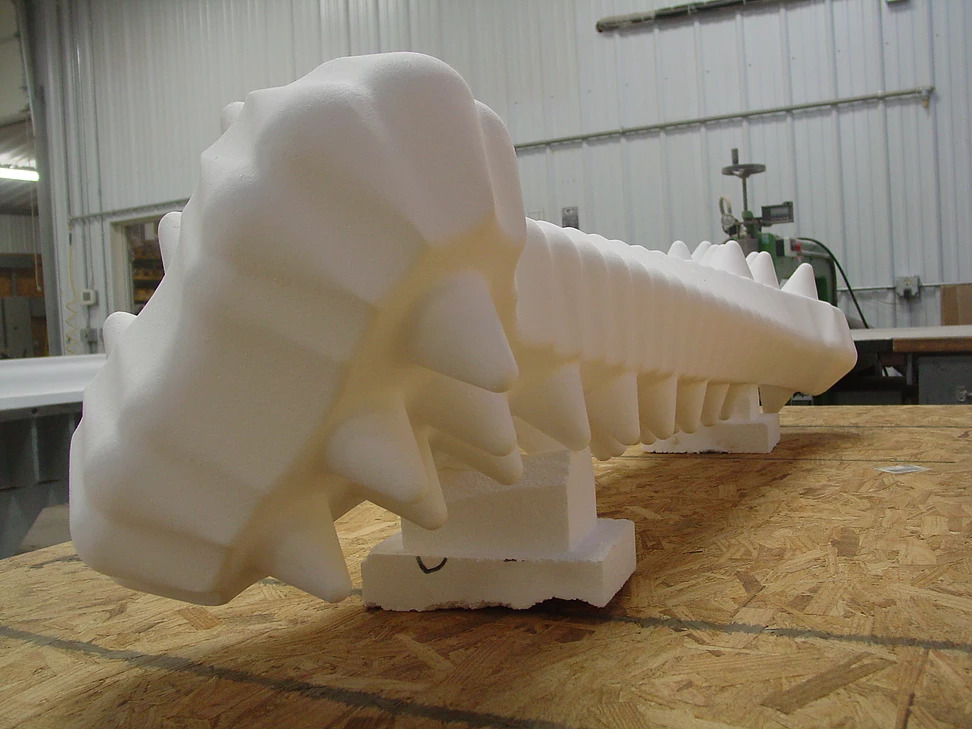

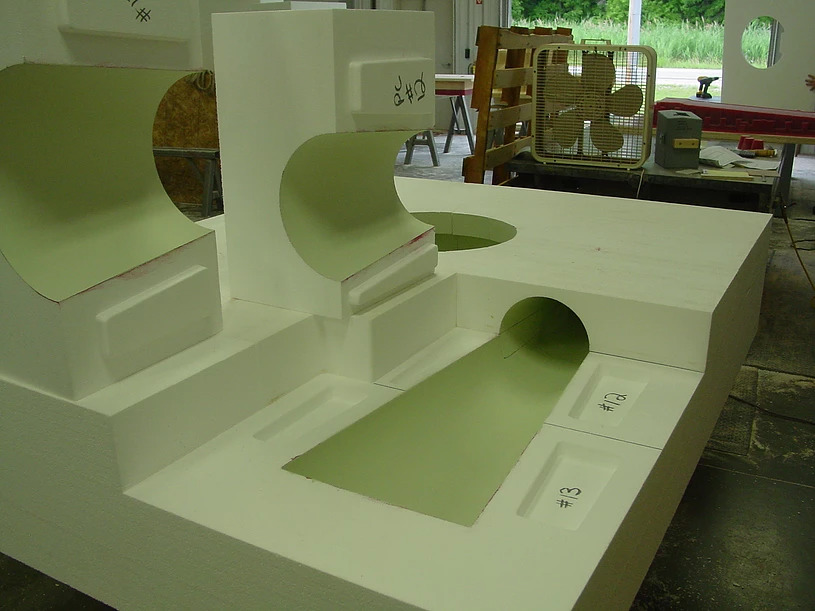

Pattern Services can help you stay on budget with your one or two off and prototype parts by providing and alternative, low cost, material such as Styrofoam. The tooling can be constructed the same as conventional wood tooling except there is no need for draft which also saves time on the design side. Thin, fragile areas, or delicate loose pieces can be substituted with a stronger material. Depending upon a few variables like complexity, handling, and sand systems there are some occasions where you may get more than a one-time use.